This winter I have had about 18 hours of power cuts. I know that I live in the country and I can expect some loss of power, from time to time, but 18 HOURS? It was the same last year, and the year before. Another thing, why is electricity so expensive her in Sweden? At the time of writing this article, in the USA it costs between 7 and 15 öre (in Swedish money) per kWh. Here in Sweden it costs 120 öre (1.2 kronor), which is about 25 cents US.

Wouldn't it be nice if I could generate my own power?

This article is all about alternative power, or backup power for covering power cuts. There is a lot of text, so I have colour-coded the text blocks to make it easier for you to see the different headings and subjects.

Project Magnitude (5 questions)

As I see it, there are three possibilities, or levels of magnitude, for alternative power in a single household. It depends upon the required goal. There are really three possibilities:

I will do the first, that is my minimum goal. The second item would be an easily achievable goal, to varying degrees, it just depends upon how far you want to go. The third option may be a bit too much for a mere mortal like me. But before I can proceed I really have to ask myself a some basic questions:

As much as I can! I have to consider just how much I need from a day-to-day perspective, and what I would need in an emergency. During a power cut I want to keep running some basic items. Power cuts are so short that the refrigerator and freezer will not defrost, but what would be necessary?

By adding all this up one gets a TOTAL budget of 800 Watts maximum, but since I can switch off the computer monitor, and the boiler only runs at 100 Watts for 75% of the time, I can reduce that budget to only 475 Watts. Ok, so a short-duration capability of 900 Watts, and 500 Watts continuous will do the trick.

To generate 500 Watts continuous for 4 hours, all I need is battery storage. At 25 volts, 500 Watts is only 20 Amperes, so allowing extra for lack of efficiency, then 100 A/H car batteries will work fine. All I need is an inverter.

If I wanted to power the whole house and become independant, then I would have to add under floor-heating (2kW), induction cooker (3kW), oven (1kW), microwave oven (1.3kW), refreigerator and freezer (160W), dishwasher (2kW), washing machine and tumble-drier (6kW). In total, about 15kW would be needed, assuming everything was switched ON at the same time. In reality, I could get away with about 8kW and make sure that certain combinations are not allowed, such as cooker + underfloor-heating + washing machine + tumble drier, all at the same time.

In short, I can leave the "occasional heavies" connected to the main power, but generate only enough to power the light-long-term stuff. To a lesser degree I can just provide power for lighting, heating and telly during power cuts. It is this last that I am most interested in. If I can provide something continuous on a long-term basis then all the better.

I have given this aspect a LOT of thought. I initially need only 4 hours to cover power cuts, so I can use the mains supply to charge batteries. BUT if I decided to generate continuously then I would need another source of energy.

I could use petrol, wind, and solar energy. Petrol would be for emergencies only, because of the price. Solar energy is not really available in Sweden in the winter, when it is most needed. I have no river or stream on my land, so it must be wind, unless I want to experiment with steam. I DO have a lot of trees, but not all that many. So let us stick to wind power.

If I put up a nice 10cm Dia. aluminium pole with 6' (2 meter) diameter blades, then I can generate about 2kW. This is perfect, since 35% operation is normal because there is no wind for most of the time. But a convential wind-turbine will waken up the neighbours, not to mention the local council and tax authorities. They want energy tax, planning permission, safety certification, bribes, you name it!

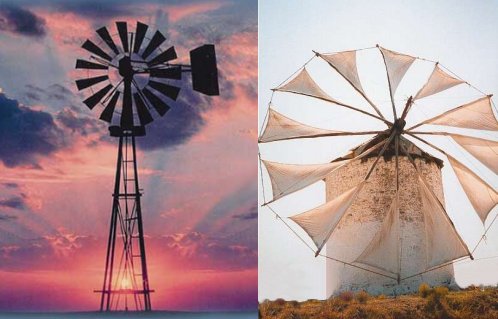

I would like to build a model of a Dutch windmill. You know the ones, the ones used to pump water so people can take their fingers out of the holes in leaking dykes. Cloth sails, LED lamps behind model windows, and a little old man at the back turning a handle. I want the neighbours to point at it and have a good laugh, with not a thought for reporting anything to the taxtman, or local authorities.

I could later on extend the mill with another model, such as the 32-blade mills you see in spaghetti-western cowboy films. You know the ones? The ones that make those "klackerty-klackerty" noise in "For a Few Dollars More", and "Gunfight at the OK Corral".

I also have a mini-tractor that is used to plough snow and cut the grass. I presently have a charger that puts 50mA back into the battery, continuously. That way the tractor is always fully charged and ready for action. I can use the motor from a Hard Disk to generate that much, saving me money on the extension cable I presently have dragged across the garden. More details about this later.

For emergency use, ie flat batteries, I may need to charge the batteries. I can do this with an old 3.5HP lawn-mower engine I have in the garden shed. I can mount this on two planks and belt-drive two 12V car alternators. Small alternators will deliver 50 Amperes, so I can charge the batteries twice as fast as I discharge them.

My mini-tractor has a 15HP engine. I could belt-couple this to an 8kW generator, but the generator will cost me SEK6000 (US$950). For the moment this is out of my pocket, but it is a future possibility.

Initially I want to keep the house "ticking over", so we can both have a comfortable existance during power cuts. For that I am prepared to spend a LITTLE money. I am NOT prepared to spend a great deal. In this case there is absolutely no cost saving, just expense.

I understand that I would have to replace batteries every 5 years, but at Swedish prices, this is only a small fraction of the electricity companies monthly bills. If I can also generate a little "free power" then I will be happy, and hopefully break even.

Windmills, lawn-mower generator and car alternators can all be bought or built for almost nothing, especially if one is prepared to use second-hand units. All the power that comes out of the windmill generator is free. THAT is my kind of price. All I need to do is use a bit of timber and arrange a belt-drive to give a 1:10 mechanical advantage, and use slow-moving cloth sails to catch the wind. This is where the cost savings are to be made.

Yes!

So far, it all looks quite practical. The main stumbling block could be generating 220V AC from 25V DC at sufficient power level. It's also a question of degree: how far do I want to go. But at least I now know that I can do something.

To really practical, this project is a time-eater. If I stated this with a fanatical devotion then I doubt if I could finish it in my lifetime, but I can do something prctical, and hopefully save a few dollars along the way. If I can generate a small power and drive the computers, then build another mill to power lighting, I could have several sources of free energy, each supplying a different area. That is about my limit. One big generator is not practical for me.

Here I intend to generate up to 100 Watts from 12v so that I can run equipment that is not sensitive to frequency, level or waveform. This means lighting, including flourescent and economy lamps. It also includes transformer-operated equipment. It does NOT include any device using AC motors or Switch-Mode Power Supply units (SMPSU).

This inverters main advantage is the few components required. You can "throw it together" in 30 minutes. If you have a 12v soldering iron then you can build it and put it into operation during a power cut. I know this because I have done it.

The circuit operation itself is nothing more than a simple multivibrator.

The transformer in this circuit can be any mains transformer that will take the power, but with two identical secondaries, or a "split secondary" winding. For example, a 230v - 12-0-12v transformer can be used in this circuit to convert 12v DC to 230v AC. A 117v + 117v to 12v + 12v can be used to do exactly the same job. The split primary in this case will alternatively let you take 117v AC out.

The two resistors in the circuit must be rated at a sufficient power level that they will not burn. For a 12v inverter you can use a pair of 14v 0.1A indicator lamps, since these are cheaper than 1.5 Watt resistors (here in Sweden). If you want a 48v DC input 500 Watt inverter, then use 100W 230v lamps.

As a general guide, here is a table of components for various power and voltages, but these may vary a LOT if you use different transistors.| Power level | Transformer primary | TR1 = TR2 | Resistors R |

|---|---|---|---|

| 1 Watt max | 12v + 12v | BC547 or 2N2222 | 4K7 |

| 1 Watt max | 24v + 24v | BC547 or 2N2222 | 10K |

| 3 Watt max | 12v + 12v | BFY51 or 2N3053 | 4K7 |

| 3 Watt max | 24v + 24v | BFY51 or 2N3053 | 10K |

| 10 Watt max | 12v + 12v | TIP31 | 1K0 |

| 10 Watt max | 24v + 24v | TIP31 | 2K2 |

| 30 Watt max | 12v + 12v | TIP31 | 330R |

| 30 Watt max | 24v + 24v | TIP31 | 680R |

| 30 Watt max | 48v + 48v | TIP31 | 680R |

| 100 Watt max | 12v + 12v | 2N3055 | 47R |

| 100 Watt max | 24v + 24v | 2N3055 | 100R |

| 100 Watt max | 48v + 48v | 2N3055 | 220R |

The output of this inverter will normally tolerate a short-circuit, but the output frequency will vary considerably, possibly from 35Hz with no load, to 150Hz with full load. But for loads with transformer input, and for lamps, this is quite acceptable.

The only other "foyble" is that the output waveform tends to have a leading spike of about 1000 volts. A 10nf 500v AC capacitor across the 220v winding will fix this.

Converter #1 above can be built in a few minutes. I proved it this weekend. I assembled the inverter, laid on a bit of wood, and ran nine 11-Watt ecconomy lamps. Since each lamp is "supposed" to be equivalent to 50-Watts, I had the equivalent of 450-Watts of lighting, and sustained it for two and a half hours. I did not use a heatsink on the transistors, but I did use a 12v computer fan to blow in the transistors, just in case.

The circuit is quite simple to build. All you need is seven leads with corocodile clips (aligator clips) on each end, two transistors per 100-Watts (at 12v), two 330-Ohm resistors, and a 120-Watt transformer. I also used a pair of plastic beads so that when I twisted the ends of the resistors on the BASE connection, there was no danger of the wire touching the transistor case.

The leads should all be at least 3mm cross-sectional area and have an insulated crocodile clip. If there is any tendency for the leads to get warm, or even make a noise, then use two or more leads in parallel. Do not coil the leads. The important ones are RED and BLUE in the drawing. I did find that many of these jumper leads are somewhat cheap, and the connections are not always so good at the clip. Mine had a tendency to "buzz" in sympathy with the transformer oscillations. But it all went well and I fed the lamps.

I fitted a short plastic tube over the two transistor leads. You could just poke the BASE and EMITTER wires through a bit of card, but I used the Ikea "PYSSLA" plastic play-things from the Childrens section. For half-a-dollar you get 18,000 of them. The 330 Ohm resistors are twisted tightly around the transistor legs so that it is good and secure.

I built the whole inverter using candle-light and absolutely NO tools for connecting, stripping, or making joints. It was all up-and-running in less than 15 minutes, but this did include a search of the workshop for "something" to insulate the transistor leads. The 330-Ohm resistors may be a bit too high. If oscillations stop at full load, then drop them to 100 Ohms, or even less. I tried 330 Ohms because smaller resistors burn. I eventually put another 330 Ohm in parallel with them on this version. If you have lower-gain transistros then you will need a lower value here.

This converter is a lot better, more reliable, but it is a little more complicated. The output frequency is 58Hz from my first bench prototype, under all load conditions. The inverter does not stop when it is overloaded; it keeps on delivering power at a lower voltage. The output is still a square-wave. This means that it cannot power synchronous motors or Switch-mode power supplies, but it will deliver up to 1000 Watts to power lighting and transformer-input equipment. Just for a laugh, I have even run a coffe-maker with this circuit.

The heart of this circuit is a pair of PNP transistors, TR1 and TR2. These operate from a stabilised 8v supply. I didn't have an 8V regulator, so I put a 1K0 resistor in the Gnd terminal of the 78L05 5V regulator. The 78L05 has a standing constant-current of 300uA to ground, so adding a resistor here raises the 0V reference level.

The multivibrator drives a pair of low-level NPN transistors, TR3 and TR4. This PNP-driving-NPN arrangement ensures the two square-waves do not overlap, otherwise we would end up with two power transistors pulling in opposite directions. The two NPN transistors also buffer the oscillator from any possibility of changing loads that could cause the frequency to vary.

These two NPN buffers drive a pair of PNP power transistors, TR5 and TR6. TR5 and TR6 are fed from the un-regulated power, whether it be 12V, 24V, 36V, or whatever. They will drive about 1.5 Amperes into "a load". This load could be a 24-0-24V transformer to deliver 30 Watts. This is perfect to rectify to drive valve circuits, or even older hamradio rigs, such as the FT101, or older Heathkit stuff. Connect points X X directly to a 30-Watt transformer.

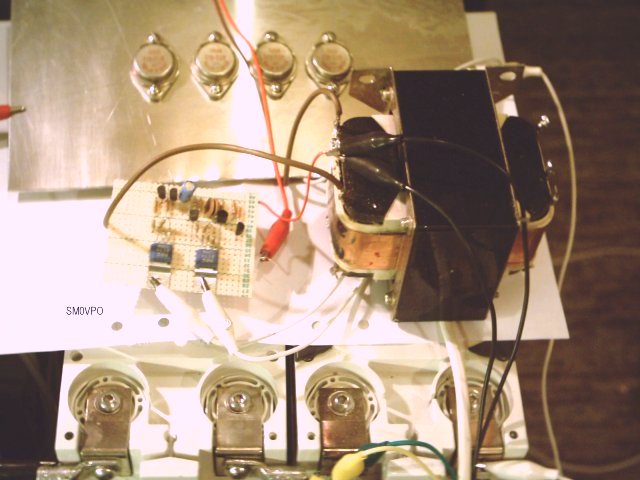

Note that in this case the transformer center-tap is connected to Ground, Chassis, or Earth. This is convenient in that you will reduce a little electrical stress from the transformer, but when you use the higher-power inverter it makes construction cheaper. Here is my prototype on the bench. I built it in protyping board. It is sitting on 24-volt maintennance free lead-acid batteries.

As you can see, the board works, the transistors are bolted to a simple aluminium plate, and you can see the transformer I used. I have used temporary jumper leads, but they do get a bit warm, even using three parallel leads for the +ve and -ve power. But I can still pull 500 Watts.

For higher power, up to 1500 Watts, you need to add a pair of NPN power transistors, TR7(8) and TR9(10): 2N3055. In general, add a pair for every 250 Watts required. If you want 500 Watts then you need four transistors, 750 Watts = 6 transistors, etc. These transistors are mounted on a heatsink WITHOUT insulators. This gives better thermal contact, and allows a good tight electrical bond between all transistor cases. TR7 and TR8 are used in common-collector mode, or emitter-follower. This means that even the 1.5 Amperes drive current from TR5 and TR6 will also be used in the output transformer, instead of being wasted.

If you cannot get a 1000 Watt transformer, then use two identical 500 Watt transformers, or even four identical 250 Watt transformers. Just be sure that the output windings are connected in paralle1, and in the correct phase. A good source of 250 Watt transformers with a 28-0-28V secondary is the VHS video tape recorder. Now that the analogue TV network is being shut down, people are being forced to buy new gear. This means there are loads of old TV sets and VCR units at your local scrapyard.

If you want to be a bit more ambitious, then get these cheap 500W 230v to 117v converter transformers, made in Spain. They are a load of absolute crap, BUT you can take them apart and re-wind them to suite the voltages you want. You should choose the highest DC battery voltage you can afford. 48 Volts is good, but 24 Volts is quite usable, up to about 1000 Watts.

When you dismantle these transformers, lay out the "E" and "I" laminates and spray them lightly on one surface, with varnish to insulate them. When the varnish is dry, place them back together and measure the size of the new former you will need. It will be bigger because the varnish has added thickness, but it is this varnish that will make your transformer more efficient, and run cool. When you wind the transformer, work out the AVERAGE currents in the windings. For the DC side it will be 1/2 the continuous input current, but for the AC out side it will be 100%. Select the approximate enamelled wire (magnet wire) size for the current you need. This table will give you a rough idea.

| Current | Diameter | A.W.G. |

|---|---|---|

| 0.5A | 0.5mm | 24 |

| 1A | 0.7mm | 22 |

| 2A | 1mm | 19 |

| 3A | 1.25mm | 16 |

| 5A | 1.5mm | 14 |

| 10A | 2mm | 12 |

Assume the wire to be square when calculating the number of turns in the "area budget". For example, 1cm x 1cm will allow you to have 25 turns of 2mm Dia. wire, assuming you wind neatly. If you "pile-wind" without order then you only get 80% of this = 20 turns.

This I already have. I was given an old 900 Watt computer "Uninteruptable Power Supply" (UPS). It will supply 900 Watts for 11 minutes with the internal 10 A/H 24V batteries. I have added 24V 100A/H external batteries in parallel with this to extend the 900 Watt load capability to 2 hours. It will power my 55 Watts portable colour TV AND video AND computers (without monitor) for over six hours.

This unit delivers a nice sine-wave output and is suitable for driving clocks and synchronous motors, such as the central heating pump. This unit is a very high-quality unit, so if you have the opportunity to get one cheap then grab it - FAST. If you don't want one then get it for me.

Generating a sine-wave is not so easy. Switch-Mode equipment will operate with a triangular waveform, but phase-sensitive equipment, such as motors, need to have a good waveforem. My 3-phase pool pump smokes if the waveform is not accurate, or if the three phases are not 120˚. In principle, the square-wave output from inverter #2 can be filtered, but the filter will probably degrade the supply regulation, or reduce the power available. But there is another method that we can employ.

In my inverters above, the driver transistors are switched hard-on, or completely-off. This means that with max voltage and no curent there is no power consumed in the transistors. But when on, then there is maximum current, but no voltage. Again, there is no power consumed. This is the benefit of digital electronics. But if I were to use an analogue sine-wave, then the output transistors would dissipate power and the converter efficiency would fall dramatically. 40% would be doing well!

If a square-wave is coupled to a capacitor through a resistor,or coil, then the capacitor will charge to the AVERAGE voltage level of the square-wave.

Hmmmmmm!!!! So if I were to vary the mark-space(on/off) ratio of the square-wave, then this average voltage level must also vary. So if I then vary the mark:space ratio from 1:99 to 99:1, then the average DC level recovered will vary from 1% to 99%. Cool!

My proposal is to feed a 5kHz triangular waveform into a voltage comparator, and compare it with a 50Hz sine-wave. The output will be a square-wave at 5kHz, but the switching point on the triangular wave will vary with the sinewaves phase angle. In theory, this should give me a nice square-wave at 5kHz,with a duty cycle that varies from 1% to 99%. Now I can use my inverter push-pull drivers and transformer to switch 24V DC in my transformer and get a 230V AC 5kHz waveform out. All I need is an inductor and capacitor filter to recover the original sine-wave, but this time it will vary from 1% (-227V) to 99% (+227V).

It is of interest that the low-level sine-wave oscillator can be controlled: frequency, level, and phase. This means that it could be possible to synchronise several inverters, and even regulate the output very easily. Use my EPROM WAV to SINE generator for generating a nice pure sine-wave.

In the square-wave inverter, the peak voltage is also the RMS value. But in this application this is not so. The transformer secondary must be 325 Volts to get 230 V AC out. You could compensate by increasing, for example, 24V DC input to 36V DC. I must also point out that idea is only theoretical and I have not (yet) tried it out. It should work, but I will add more after I have done some experiments.

This is dead simple. Burst open that old 40MByte hard disk and gently dismantle it. Do NOT throw away the unused bits just yet. Now you just put a fan on the shaft the disks were on. When the wind rotates it the stepper motor will generate power. A stepper-motor is nothing more than an alternator with several coils. Rectify and use to maintain your car battery, or the battery in the tractor you only use every third week.

Beg, borrow, or "otherwise appropriate" another 9 of those 40MByte hard disks and take them apart. The rear end of the armature has a coil beside a magnet. These magnets are megga-powerful. I put one on the refrigerator door but Maj-Lis had to have help to get to the papers it was holding. You need to prise them off. Don't forget to keep your credit cards well away from these magnets.

Super-glue ten of these magnets in a circle round the edge of a bit of wood, about 25cm Diameter. Use a compass to make sure the poles are all in the same direction.

Now you take another bit of wood and position 20 ferrous metal bolts around the edge so that they correspond to the poles of the magnets. Wind about 100 turns of thin (0.15mm Dia.) magnet wire on each bolt, and connect all the coils in series, but reverse every alternate coil.

If you rotate the disk with the magnets, then place the stationary disk with the coils near the magnets, you will generate up to 50 Watts of electricity at 30V. This is perfect for replacing the power in 100 A/H batteries so your standby 500 Watt inverter is ever-ready.

A simple set of blades on a bicycle-wheel, with hub-dynamo, fixed between alternate spokes, will generate a good solid 6 Watts.

Two aluminium plates, 5cm x 30cm, can be bolted to your hard disk motor to generate 5 Watts. Do not forget that there is no reason you cannot belt-drive several motors to get more power. If the motors load down the propellor, then use bigger blades. If the blades spin almost freely, then you can increase the load by using a larger pully at the blades to drive the motors. It is an "impedance match".

Another wind generator is the vertical blade. You see these at garages with rotating adverts. In principle, one of these will generate 100 to 250 Watts, but an oil-drum cut down the middle can generate 300 to 500 Watts. Gear up, using a pully and belt, to drive a car alternator, or use your HD magnet alternator :-)

A well-designed twin-blade propellor, with a 10cm width and a 2.5 metre (8-foot) Diameter, can generate up to 2KW in an elevated position. The blade should have a nice pitch that reduces towards the ends. Such a blade needs a reasonable breeze to set it in motion, but it performs well under high wind conditions. You should, however, use some form of braking system.

The old-fashioned flour-mill type of windmill with cloth sails will turn under slow wind-speeds. A surface-area of 2 square meters (20 square-feet) will generate 2KW. This type of mill does not like high wind-speeds, but it can be mounted at ground level. The sails can be released using a simple chord and spring to regulate the speed.

If you search the web you will find loads of information about harnessing the wind to generate power.

All you need here is an old lawn-mower engine fitted to two planks. You can then fit two car alternators and couple them by means of belts. This can generate typically 1500 Watts continuous to keep those inverter batteries permanently full. With a little thought you could also add a starter motor and a bit of electronics so it will kick-in as soon as the UPS battery-warning indicator illuminates.

Do not forget your car. You probably drive to work daily and your modern car generator generates typically 1500 Watts, or more, in a modern car. Why not add an extra 200 A/H battery in the trunk of your car, and plug the inverter output into the house when you get home? You can arrange two x 100A/H batteries in parallel with the car battery, but isolated and series-connected when the engine stops, using a relay. That way you could get power and still be able to start the car if the inverter flattens the batteries.

I also have a garden tractor that sees little use. I use it to cut grass and plough snow in the winter. I have built a heated shed for it and the battery has a 50mA maintennance charge. This means it will start any day I want it. The engine is 15 HP, which should be capable of driving a 10kW generator. If I have a budget in the future, then I could couple a belt-couple to this 8kW unit to power the whole house. It should be easy enough to start the tractor (electric start) automatically with a little electronics. Perhaps I could fit the unit to the tractor permanently during winter, instead of the extra wheel-weights?

Here in Sweden many car-parking facilities have a 230v AC outlet so you can plug in your car and keep the engine warm when it is -30˚C cold in the winter. Perhaps I can fill 12kWH into batteries from that outlet and take it home with me in the evening? Naaaa!! That would be stealing.

Very best regards from Harry Lythall